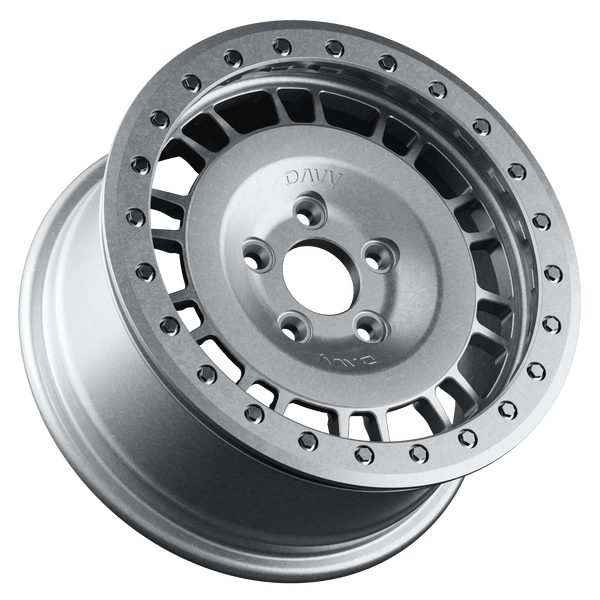

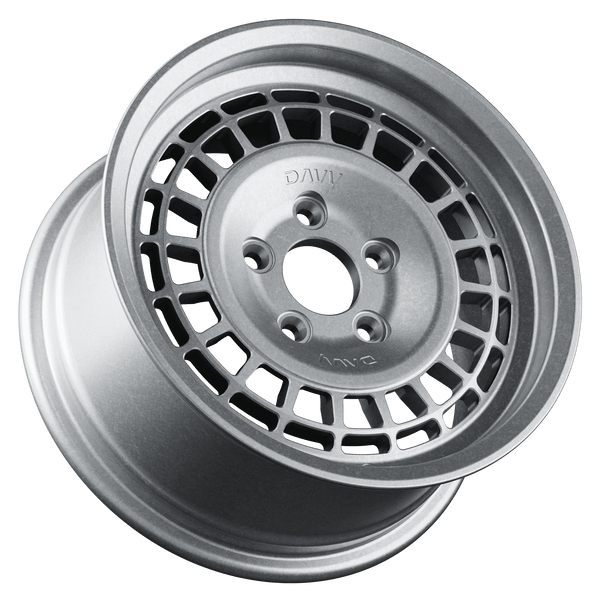

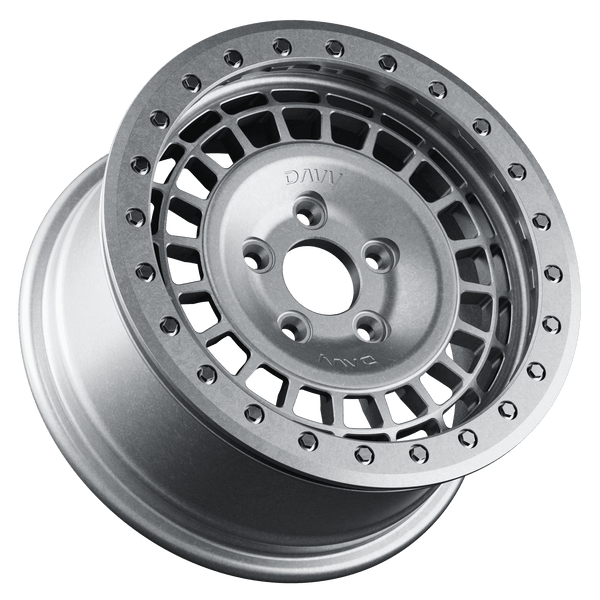

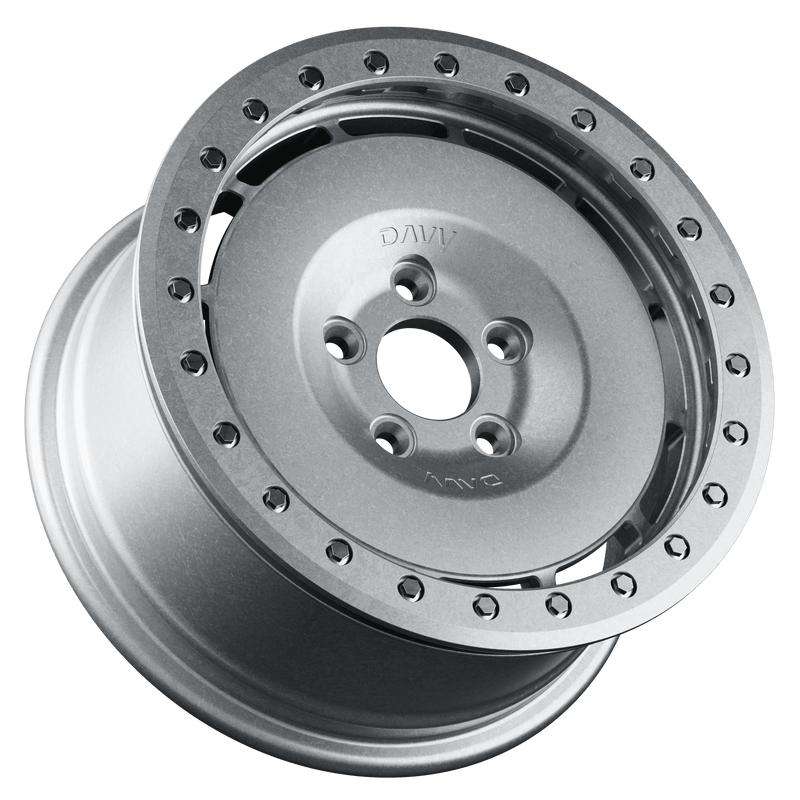

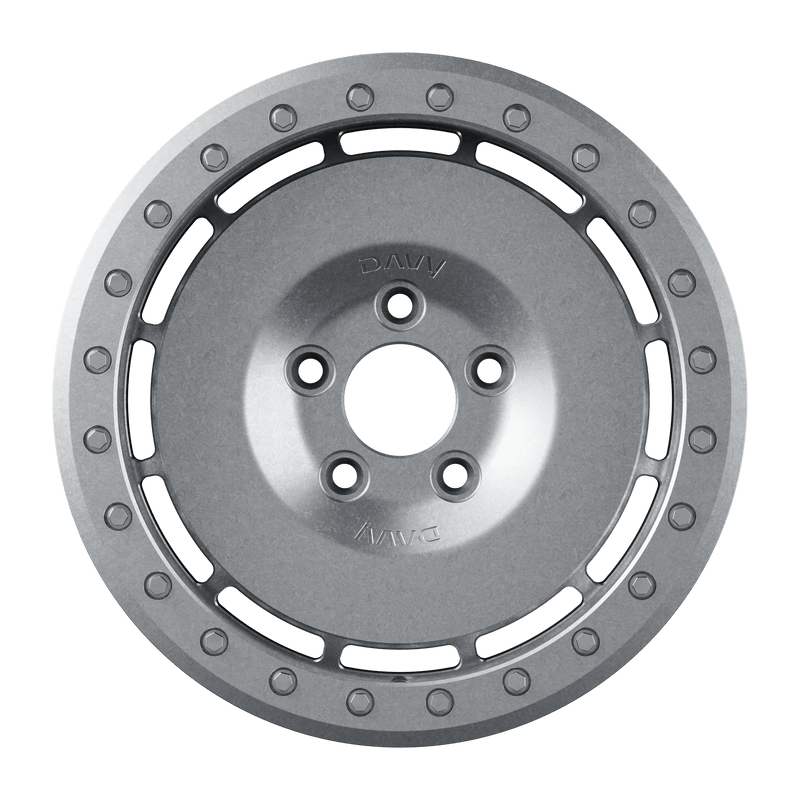

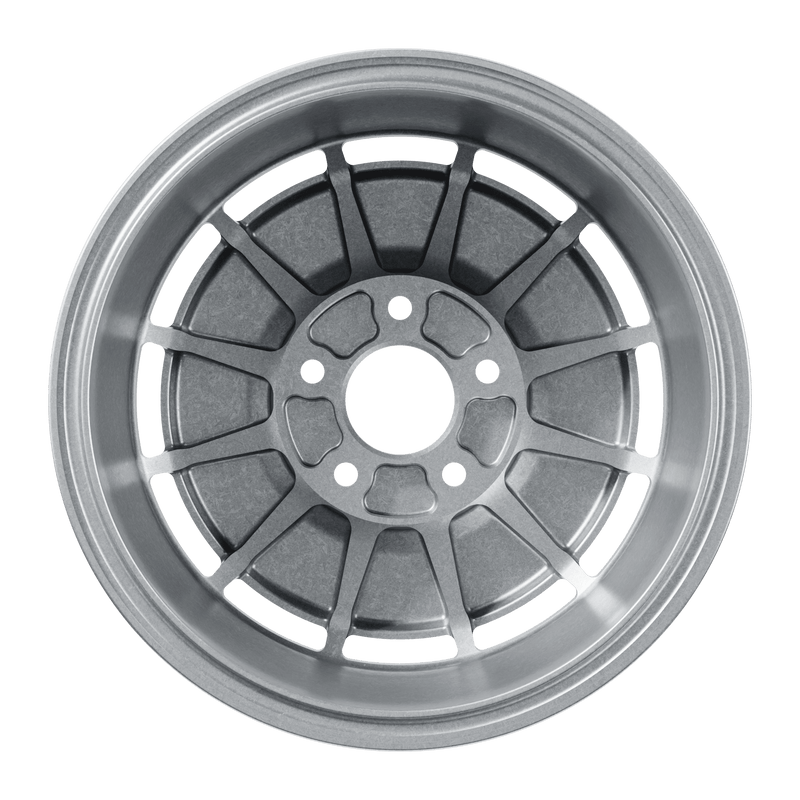

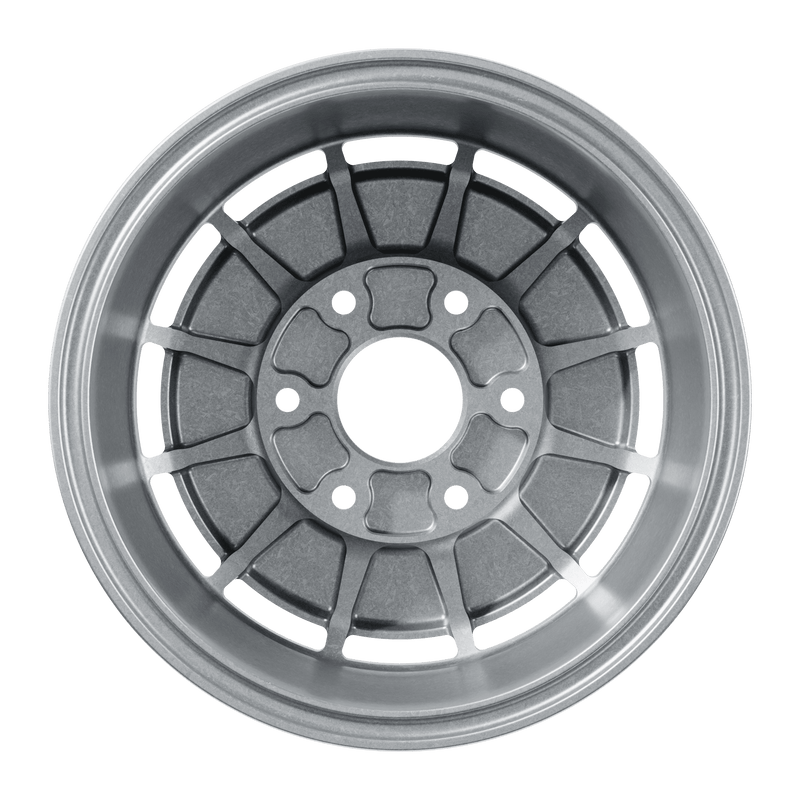

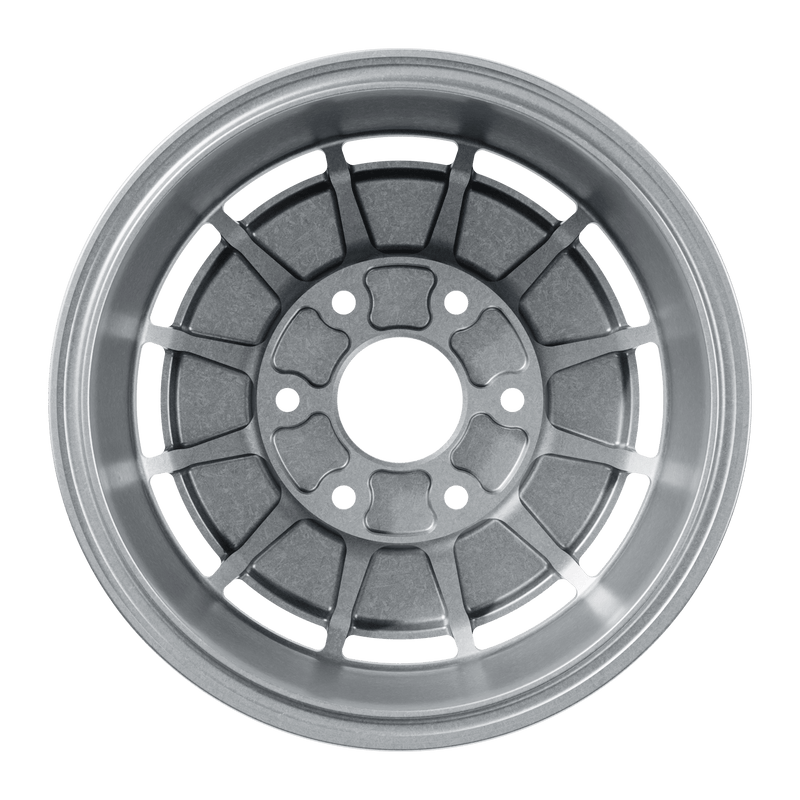

WHEEL SPECS

- VEHICLE POLARIS RZR PRO R

- MATERIAL FORGED DA-6061 T6

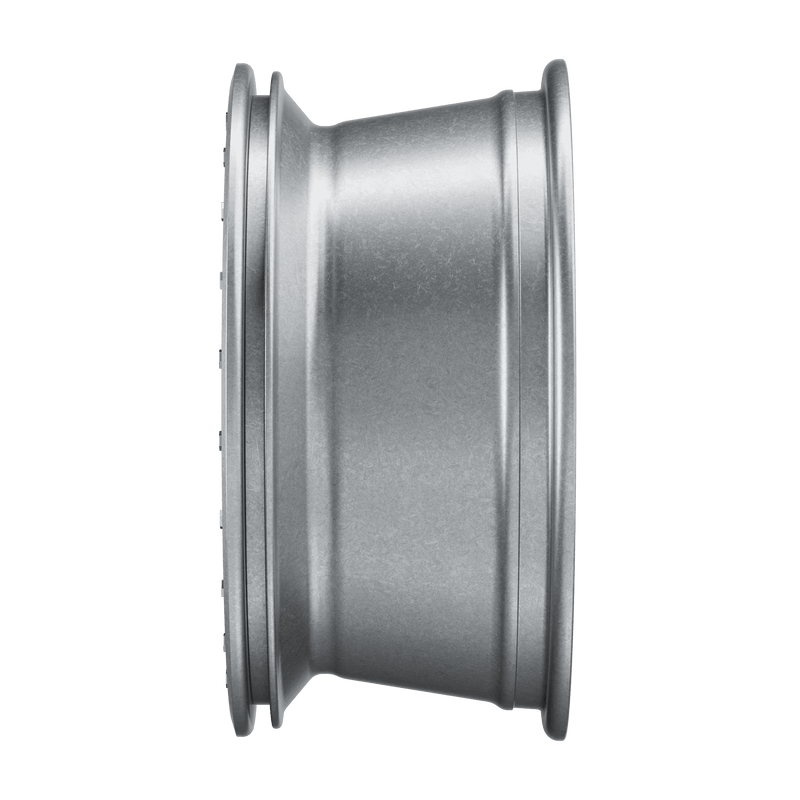

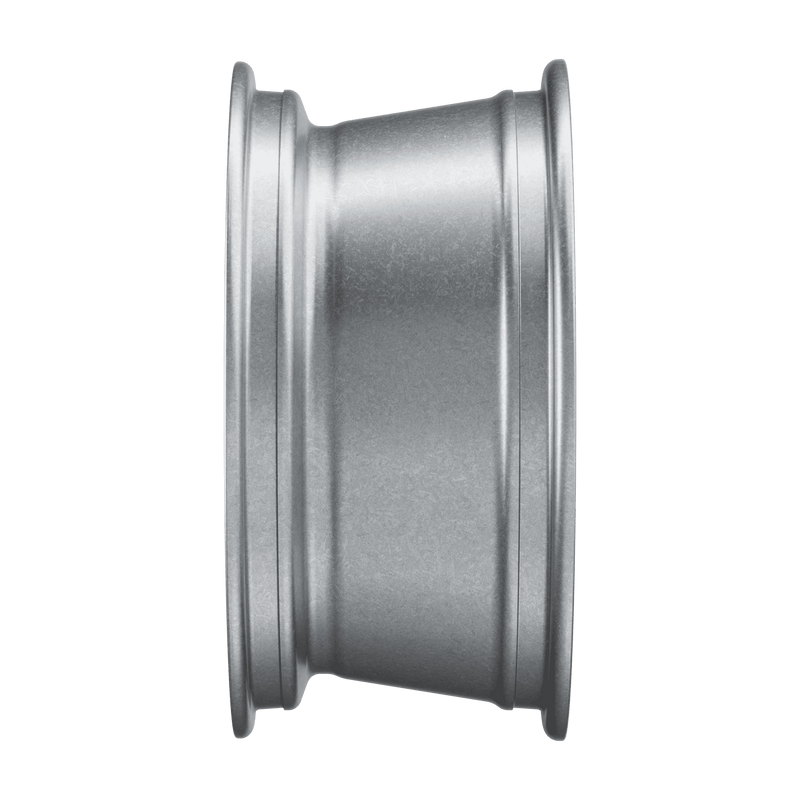

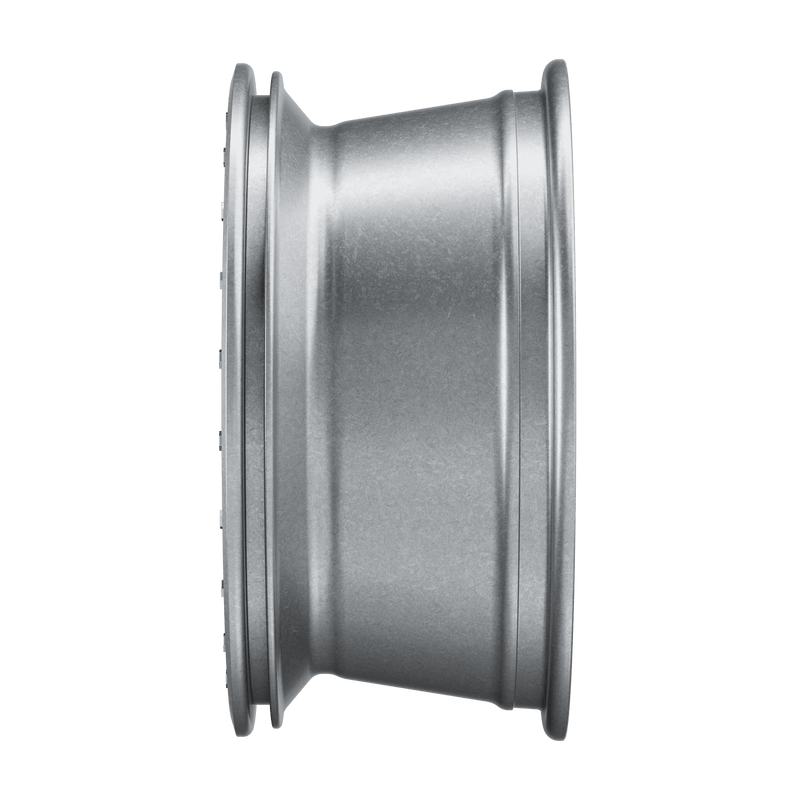

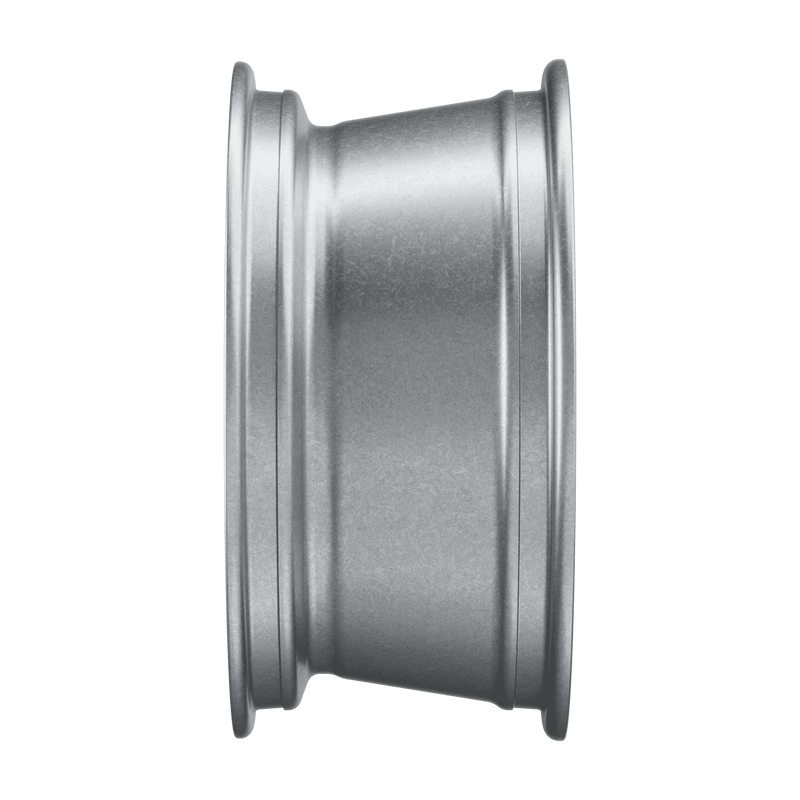

- WHEEL DIAMETER 15 IN

- WHEEL WIDTH 7 IN

- BOLT PATTERN 5X114.3MM (5X4.5IN)

- OFFSET 28 MM

- HUB BORE 70 MM

- BACK SPACING 5.125 IN

- WHEEL WEIGHT 15.69 LBS

- MAX LOAD 1,800 LBS

Lug Nuts

M12 x 1.5mm

Every Davy wheel includes lug nuts designed and engineered for Davy wheels. They feature an open-ended design for longer wheels studs and are compatible with 19mm or 3/4 socket for fast tire changes in racing environments.

Machined from heat-treated CF 4140 chromoly steel and finished in silver Zinc Flake coating for extreme durability and corrosion resistance.

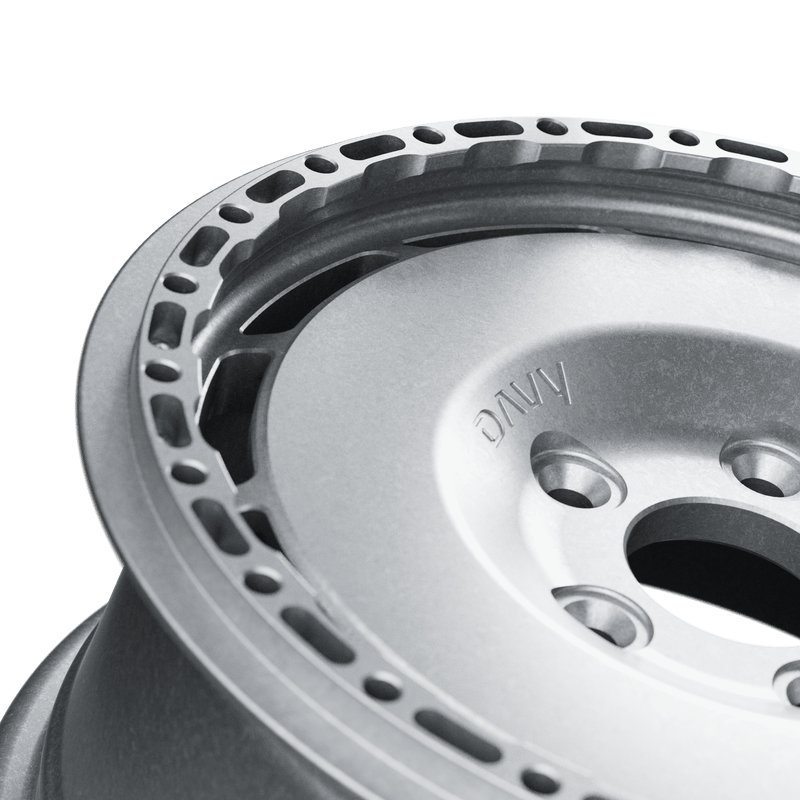

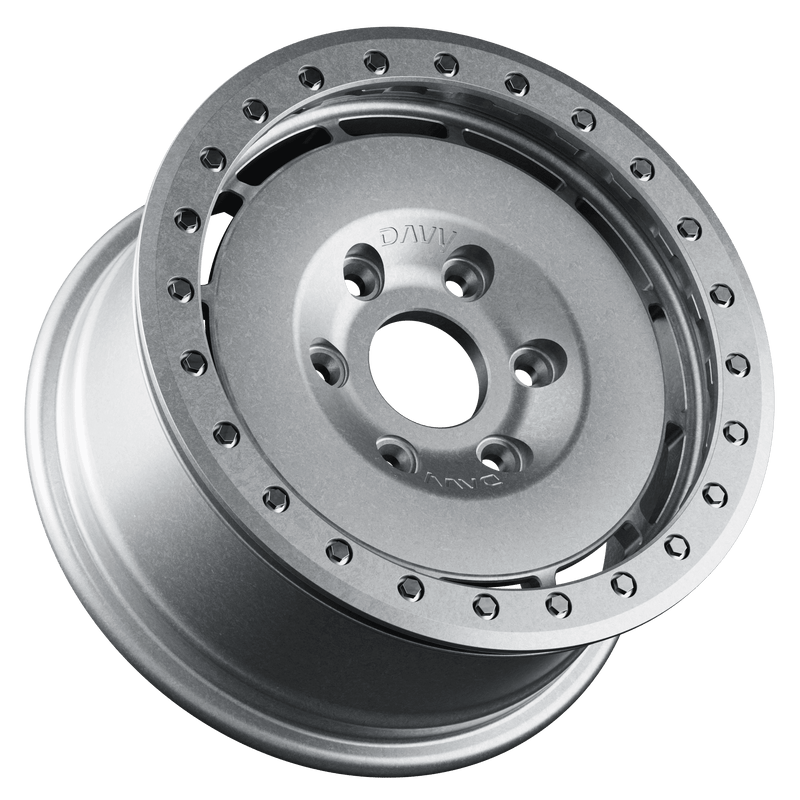

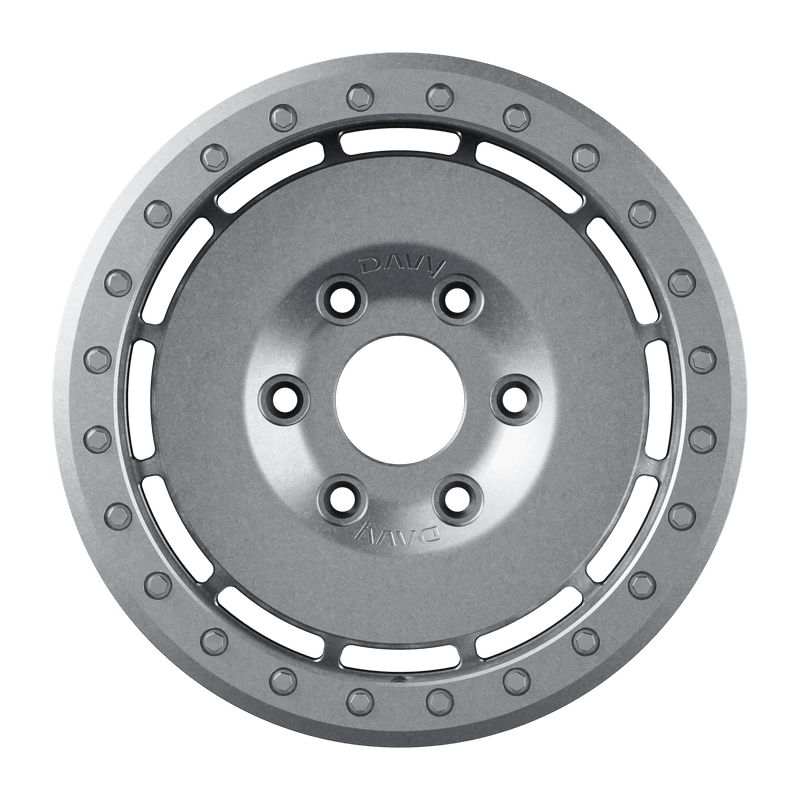

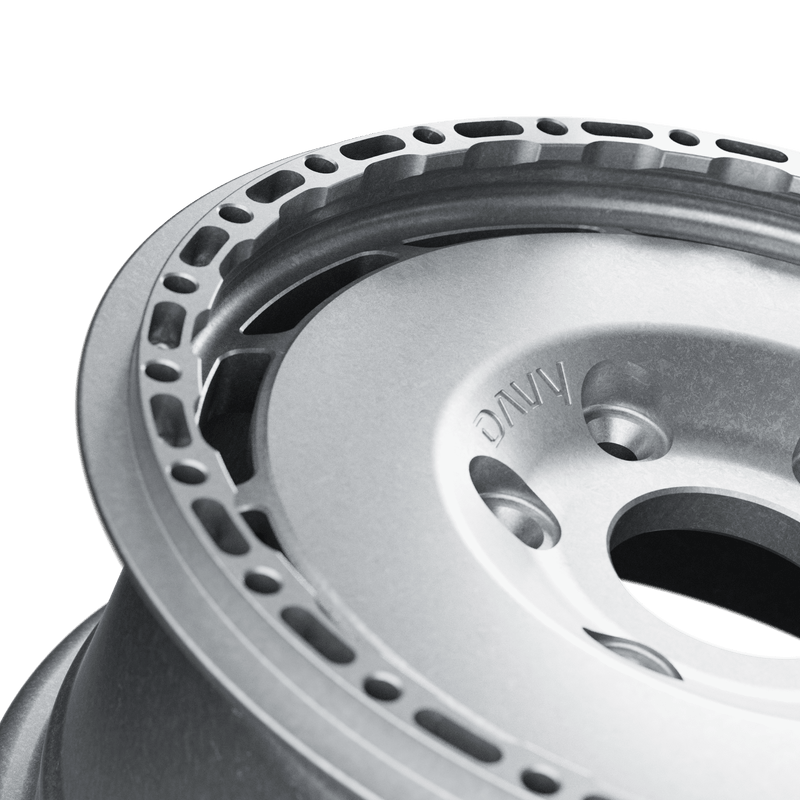

Beadlock Bolts

M8 x 1.25mm

Davy Beadlock wheels include a set of 24 ARP Stainless Steel M8 x 1.25mm bolts.Made from 8740 chromoly steel because failure is not an option.

Just make sure you know the whereabouts of your 10mm socket.

Guaranteed for Life

Built to last a lifetime, our performance wheels are guaranteed for life. Ride with confidence, knowing you’re backed by unbeatable durability.

Free Shipping

Delivered with Care

Domestic in the US, or international. Shipping's on us.

Answering Questions.

What makes DAVY wheels different from other aftermarket options?

DAVY designs from the material up — not just the surface out. While others refine form, we engineer at the molecular level, developing proprietary alloys and production methods that deliver wheels that are lighter, stronger, and stiffer.

This deeper approach to design and manufacturing drives measurable gains in performance and reliability. And wheels are just the beginning — the same material science and engineering principles guiding DAVY today will define the next generation of high-performance products across categories.

Why are all DAVY products made to order?

Because race-grade parts deserve race-grade attention.

Every DAVY wheel is machined to order from forged blanks, then individually inspected and serialized. That gives us three big advantages:

1. Latest spec, every time.

We’re constantly refining geometry, tooling paths, and surface details. A made-to-order model means you never get “old stock” — you get the current revision, built with the latest learnings from lab and field testing.

2. Tighter quality control & traceability. Each wheel has a clear chain of custody from billet to box. We know exactly which blank, which machine, which inspection, and which tests it passed.

That level of control is only possible when we’re not pushing mass inventory through a warehouse.

3. Less waste, more focus on performance.

We don’t tie up resources in pallets of unsold wheels or obsolete SKUs. Instead, we invest in better forgings, tighter tolerances, and smarter testing — and we avoid the environmental waste that comes with overproduction and dead stock.

We do keep a small reserve of forged blanks for fast-turn warranty replacements and priority riders, but every customer wheel is cut to order. It’s a bit more work on our side, but it’s the only way we’re willing to put our name on it.